Yang 6 CBM rear loader truck is built on the Howo light duty chassis, equipped with an YN4102QBZL diesel engine with a maximum power of 1 16 HP and a peak torque of 290 Nm, matched with a 6-speed manual transmission WLY. It is powerful and stable, and can challenge all kinds of difficult roads. The garbage compactor bin is made of high-tensile steel, and key parts such as the floor (4mm) and side panels (3mm) are reinforced by laser/plasma cutting and automated welding processes to ensure the durability of the body.

Asal produk:

China CEECMasa utama:

40 DaysKapasiti kerja:

6 cbmDimensi ( mm ):

6500 X 2350 X 2530Jarak roda ( mm ):

3360Kuasa enjin:

116HPJenis enjin:

YN4102QBZLPemanduan gandar:

4x2, LHDKotak gear:

WLY6TS55C 6-shift manual transmissionTeguran:

Rear tilting device for 360L and 1100L metal binsYang 6 CBM rear loader truck is built on the Howo light duty chassis, equipped with an YN4102QBZL diesel engine with a maximum power of 1 16 HP and a peak torque of 290 Nm, matched with a 6-speed manual transmission WLY. It is powerful and stable, and can challenge all kinds of difficult roads. The garbage compactor bin is made of high-tensile steel, and key parts such as the floor (4mm) and side panels (3mm) are reinforced by laser/plasma cutting and automated welding processes to ensure the durability of the body. With its efficient compaction, strong power, modular design and strict manufacturing standards of the CEEC trucks factory, the Howo 6 CBM rear loader truck has become an ideal solution for urban garbage disposal around the world.

CEEC factory

is professional manufacturer in truck area,

guarantee all products Brand-New and High-Quality.

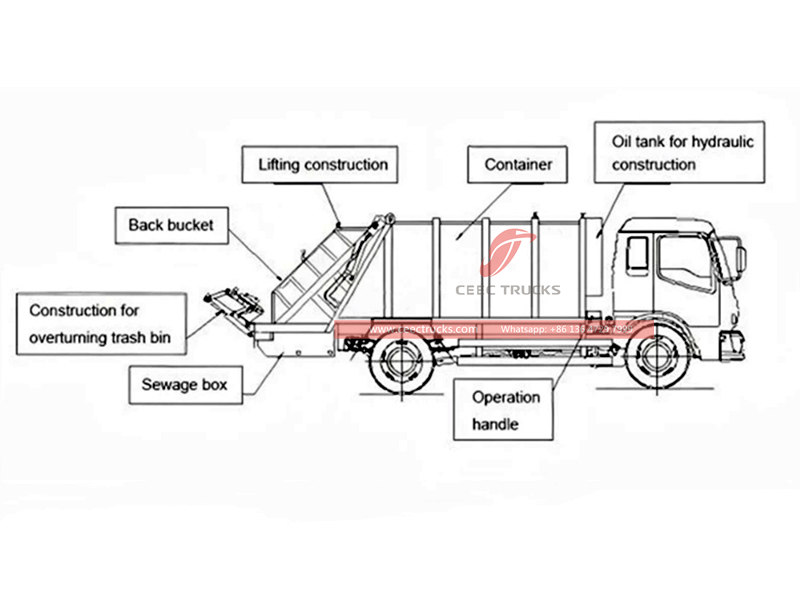

✦ Product Defination and Introduction « « «

Manufacturer: CEEC TRUCKS

Features:

1. Truck Chassis:

SINOTRUK HOWO light truck chassis, 4x2and 4x4 model

YUCHAI model with 116HP, 140HP, 160HP or 180HP

Optional EURO 2/3/4/5 emission for different market

2. Tank material:

St52 material 5mm thick carbon steel for durable service

Q355, T420, HARDOX material can be choose

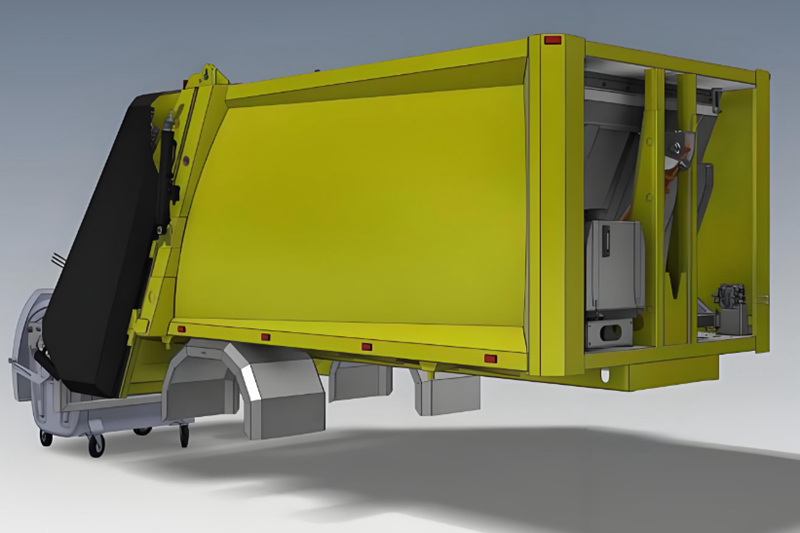

3. Tanker body:

Customized for light duty 6-12CBM compactor body, curved shape, stronger

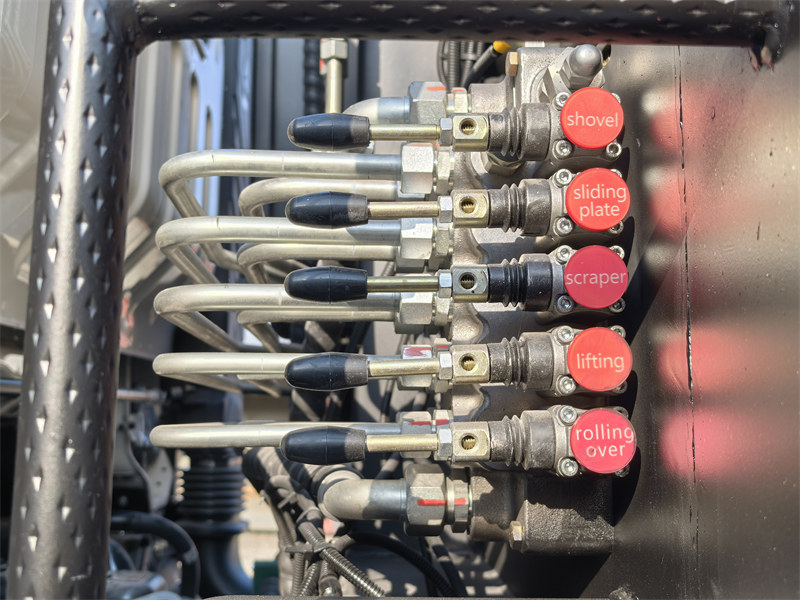

4. Control Box:

CAN BUS control box with in cabin and rear hopper, convenient operation

Also matched hydraulic control valve for emergency usage

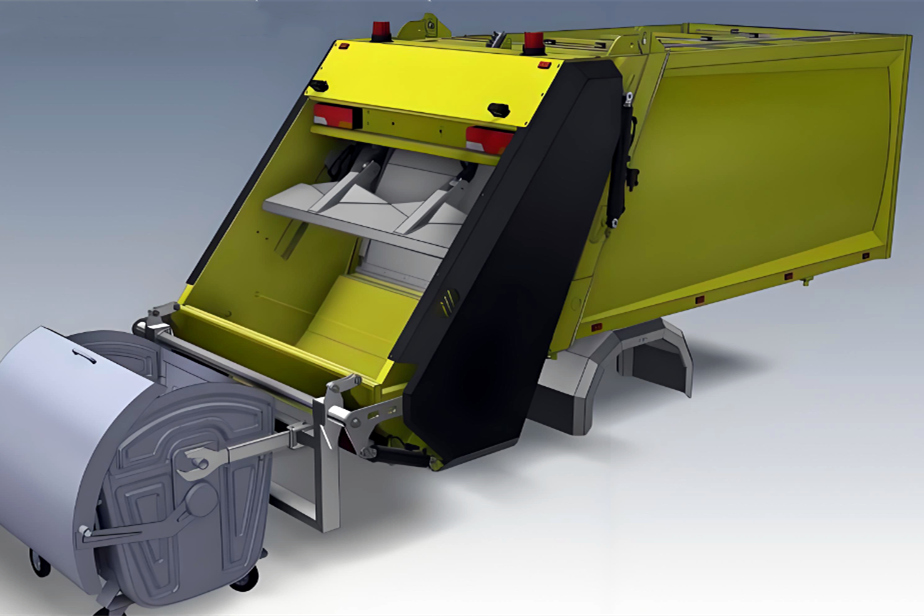

5. Rear Tilting Device: Standard 240L and 1100L bins, optional 360L, 660L, 770L, 1100L bins

6. Working Environment:

Super designed working temperature -22℃ to +48℃ day and night, with efficiently working height over 4000m

✦ Product Parameter for Howo 6CBM rear loaders « « «

|

Howo light duty 6CBM garbage R ear L oader |

||

|

Engine |

Make: YN |

|

|

Diesel 4-stroke direct injection diesel engine |

||

|

Engine model:YN4102QBZL, Euro 3 emission standard |

||

|

4-cylinder in-line with water cooled, turbocharged and intercooler |

||

|

Maximum output: 1 16 HP |

||

|

Maximum torque: 290 Nm |

||

|

Displacement: 3.76 L |

||

|

Transmission |

WLY6TS55C, 6 forwards and 1 reverse, manual |

|

|

Drive system |

Left/Right hand drive |

|

|

Chassis |

Frame: U-profile parallel ladder frame and reinforced subframe |

|

|

Front suspension:8 pcs semi-elliptic leaf spring |

||

|

Rear suspension:10+6 pcs semi-elliptic lea spring |

||

|

Fuel tank: 100 L capacity with locking fuel cap |

||

|

Steering |

Power steering, hydraulic steering with power assitance |

|

|

Brakes |

Service brake: dual circuit compressed air brake |

|

|

Parking brake (emergency brake): spring energy, compressed air operating on front shaft and rear wheels |

||

|

ABS |

||

|

Wheels & Tyres |

Tire: 7 pcs 7.00R16 |

|

|

Optional:7.50R16 |

||

|

Driver's Cab |

Howo wide cab, with three seats, A/C, electric glass, central lock |

|

|

Dimensions mm |

Wheel base |

3360 MM |

|

Overall length |

65 00 MM |

|

|

Overall width |

2300 MM |

|

|

Overall height |

2 5 40 MM |

|

|

Weight kg |

Curb weight |

4 0 5 0 KG |

|

Rated Loading Capacity |

6 000 KG |

|

|

Gross vehicle weight(GVW) |

96 00 KG |

|

|

Front axle loading capacity |

35 00 KG |

|

|

Rear axle loading capacity |

7000 KG |

|

|

Compactor Body

|

Volume of body(m3) |

6 |

|

Volume of filler(m3) |

2 |

|

|

Time of one filling cycle(s) |

≤25 |

|

|

Lifting time of filler (s) |

8-10 |

|

|

Time of discharge (s) |

≤40 |

|

|

Pressure of hydraulic system (Mpa) |

18 |

|

|

Front/rear sewage capacity (L) |

250+150 |

|

|

Control system |

CAN-bus (electrical) and manual (hydraulic) |

|

✦ Howo 6cbm Rear End Loader Truck Details « « «

1. Compactness and maneuverability optimization

►Short wheelbase body design (wheelbase ≤3.8m) + rear wheel steering assist system, achieving ≤10m turning radius

► Suitable ground clearance ( 285 mm) adapted to be driven easily on bumpy roads.

►Lightweight assembly (vehicle curb weight ≤5 tons) takes into account both load and flexibility

2. Efficient comp actor system

►Two-stage spiral comp actor mechanism (compression ratio ≥3:1) with intelligent pressure sensor

►Modular hydraulic power unit (working pressure ≥18MPa) + energy-saving start-stop control

►Sealed push plate structure (leakage rate ≤0.1%), standard sewage diversion trough

3. Intelligent operation system

►CAN bus integrated control system (including load monitoring/fault self-diagnosis)

►Reversing radar + 360° surround image (IP69K protection level)

►Remote monitoring module (4G transmission + GPS trajectory tracking)

4. Enhanced scene adaptability

►Two-way side-mounted/rear-mounted compatible mechanism (adaptable to 240-660L standard barrels)

►Wear-resistant composite steel plate carriage (HB400 hardness + anti-corrosion coating)

►Anti-slip working platform (friction coefficient ≥0.8) + LED warning light set

✦ Body Structure and Material Durabilit y « « «

⇒ Finite Element Analysis (FEA) and Topology Optimization:

CEEC Trucks Group simulates the entire process of waste compression and unloading, accurately identifying areas of concentrated stress.

Based on this, topology optimization is performed to achieve light weighting while maintaining strength.

|

|

⇒ High-Strength Steel Plates and Wear-Resistant Materials:

High-strength wear-resistant steel plate T420 is used in key load-bearing areas, with a Brinell hardness (HB) of 400 or higher.

The main body plates should be made of high-strength weather-resistant steel or galvanized steel, and the design avoids areas prone to water accumulation.

⇒ Welding Process and Corrosion Protection:

Welding must be automated using robotic welding to ensure weld penetration, strength, and consistency.

Key load-bearing welds require non-destructive testing (e.g magnetic particle or ultrasonic testing).

CEEC Trucks Group uses cathodic electrophoretic primer to enhance corrosion resistance.

Products--100% Customized Level One!

1.we can do the designs according to the your requirement .

2.we can offer you the high quality & reasionalble price

3.we can offer your a reliable after-sell service

4.we have skilled professinal design team

5. promptly delivery. any order is welcome.

We CEEC also supply spare parts (original, OEM, and replacement) for all types of trucks and trailers with discount and nice quality to ensure our customers's trucks and trailers being in good working conditions.

★ China YUNEI YN4102QBZL Euro 3 diesel engine, super powerful

★ FAST Manual 6-shift mechanical transmission gearbox

★ 12 months fast moving spare parts for FREE

★ Authorized Howo 6cbm rear loader exporter

★ Training service for Howo 6cbm garbage compactor truck

Pembekal dan pengeksport trak pemuat belakang profesional China, kami membekalkan trak pemuat belakang berkualiti tinggi. Kami dapat memastikan masa penghantaran yang cepat dan jaminan 12 bulan untuk trak pemuat belakang kami. Trak pemuat belakang kami dijual ke lebih 80 buah negara termasuk Eropah Timur dan negara-negara CIS, Afrika, Asia Tenggara, Amerika Tengah dan Selatan, Timur Tengah, dll.

---- Maximize save your sea freight.

---- Professional guidance on your importing documents.

---- Safety, Quickly, Timely

---- Service more than 60 countries.

---- Professional guidance on your importing documents.

---- CO, FORM E, FORM P, Pre-shipping Inspection...

Tag panas :